Welcome to the website of Dongguan Xinya Testing Instrument Technology Co., Ltd.!

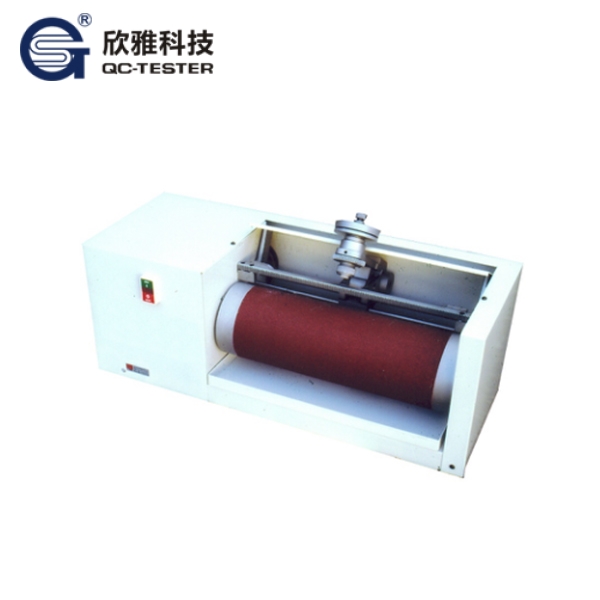

| Wear test piece | Diameter 16 mm, height 6-16 mm |

| Wear load | 2.5N, 5N, 10N |

| Wear roller | Diameter 150 mm, speed 40 r.p.m. |

| Abrasive sandpaper | # 60 |

| Moving stroke | 4.2mm /R.P.M. |

| Wear stroke | 40 m (idling without wear) |

| Wear rate | 19.2 m/minute |

| Auxiliary accessories | Sandpaper, standard glue, test piece rotary knife |

| Machine weight | 40 kg |

| Apparent dimension | 85×32×40cm (W*D*H) |

| Electric source | AC -220V 50 ~ 60Hz 3A |